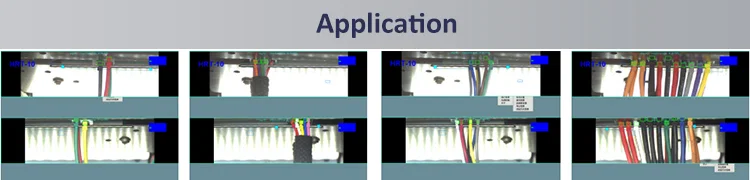

Double Row Connector Harness Tester WPM-DC20

Model No: WPM-DC20

Specifications

Wire Color Sequence Detector, Two-row Connector Wire Sequence Detector, Color Sequence Of Double-row WiresCamera pixels 1280*1024; 60FPS COMSProgressive lens parameters megapixels: 75mm F1.4Field of view 1-58mmDetection time within 0.25Power consumption within 35WMotherboard embeddedThe main MTBT >50000 hoursKeyboard and mouse standard mouse, built-in screen keyboard, external interface USB- Inquiry now